Ever wondered why construction projects sometimes run into costly delays or on-site conflicts? The culprit often lies in how drawings are interpreted. While design plans provide the big picture, Plumbing Shop Drawings translate that vision into practical details contractors can actually build from. Understanding the distinction can mean the difference between a smooth installation and an expensive do-over.

The Role of Design Plans

Design plans are essentially the architect’s or engineer’s dream on paper. They’re high-level documents that show how a project should look and function once completed. Think of them as the Google Maps overview before you zoom in—broad strokes that outline direction but not the fine print.

- Prepared early in the project lifecycle

- Focus on aesthetics, functionality, and compliance with codes

- Used to obtain approvals and permits

For example, a design plan might indicate where bathrooms are located in a hospital but won’t specify the exact pipe sizes, valve locations, or slope requirements. That’s where shop drawings step in.

What Are Plumbing Shop Drawings?

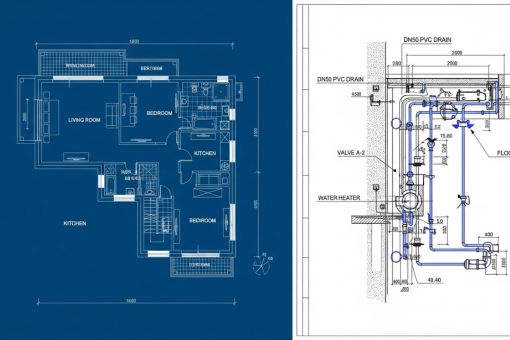

If design plans are the dream, shop drawings are the instruction manual. Plumbing Shop Drawings provide the nitty-gritty details contractors, fabricators, and installers need to turn concept into reality. These drawings illustrate dimensions, materials, connections, and installation specifics in a way design plans never do.

- Precision: Include exact pipe runs, slopes, and fittings.

- Clarity: Highlight connections between plumbing, HVAC, and electrical systems.

- Fabrication ready: Provide details manufacturers and installers can follow directly.

In short, shop drawings eliminate guesswork and minimize clashes between different trades working on-site.

Key Differences Between the Two

Let’s break down the main contrasts between design plans and plumbing shop drawings:

- Purpose: Design plans communicate vision; shop drawings communicate execution.

- Detail level: Design plans are general; shop drawings are highly detailed.

- Audience: Design plans are for approvals; shop drawings are for installers.

- Timing: Design plans come first; shop drawings follow once details need precision.

Where Coordination Drawings Fit In

In complex projects, there’s another critical layer—coordination drawings. These integrate multiple systems—plumbing, HVAC, electrical, and structural—into a single view. Without coordination, clashes are inevitable. Imagine discovering mid-project that a plumbing pipe cuts across an HVAC duct: not only frustrating but also costly to resolve.

In fact, studies show rework due to design conflicts can add up to 5% of total project costs. That’s a hefty price tag for something preventable.

Real-World Example

Picture a new hotel construction. The architect’s design plan lays out guest bathrooms beautifully, but when contractors review the shop drawings, they notice the specified pipe slopes would clash with structural beams. Thanks to detailed shop drawings, they can adjust routing before installation begins—saving weeks of rework and thousands in costs.

Related Drawings in MEP Projects

While plumbing shop drawings are vital, they’re often created alongside other specialized drawings:

- HVAC shop drawings for ducts, vents, and equipment layouts

- Electrical shop drawings for wiring, conduits, and panel boards

- Structural shop drawings for steel, concrete, and load-bearing details

Together, these ensure that every piece of the puzzle fits seamlessly.

FAQs on Plumbing Shop Drawings vs Design Plans

Why can’t contractors rely only on design plans?

Design plans lack the technical detail required for construction. Contractors need shop drawings to avoid errors and ensure installations are accurate.

Who prepares plumbing shop drawings?

Typically, specialized MEP engineers or drafting professionals create plumbing shop drawings based on approved design plans.

How do coordination drawings reduce conflicts?

They overlay plumbing, HVAC, and electrical drawings into one integrated view, helping detect and solve clashes before construction starts.

Are shop drawings required for all projects?

Not always, but for large or complex projects, shop drawings are essential to ensure precision, safety, and compliance.

Final Thoughts

Design plans may set the stage, but it’s plumbing shop drawings that bring precision to life. Together with coordination and related MEP drawings, they prevent costly clashes, enhance collaboration, and ensure projects stay on schedule. The bottom line: in construction, the details aren’t just details—they’re everything.

Also Read: Plumbing Shop Drawings: From Paper to Perfection

Blog Development Credits

This blog was a team effort fueled by smart ideas. Soumyajit Sardar picked the topic. Most content was crafted using tools like ChatGPT and Google Gemini. The Digital Piloto team polished and optimized the blog to ensure it’s clear, engaging, and SEO-friendly.