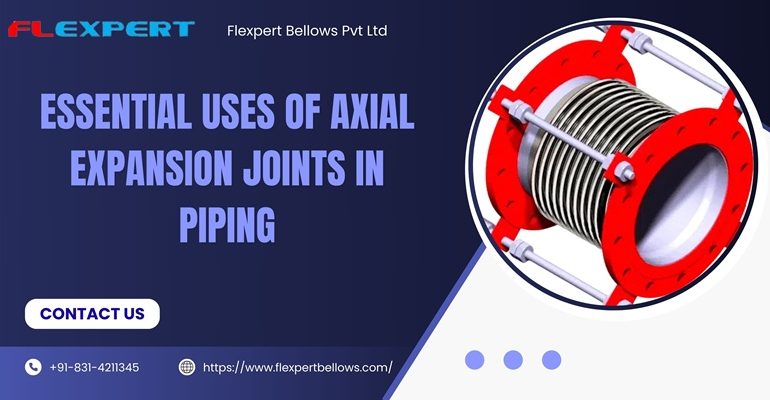

Have you ever wondered how vast networks of pipelines manage the constant push and pull of heat, pressure, and movement? The answer often lies in the clever use of axial expansion joint manufacturer solutions that silently protect modern piping systems across India’s industrial backbone.

Why Axial Expansion Joints Matter

Picture a long metal pipeline stretching across a refinery or power plant. Now imagine it expanding and contracting every time the temperature swings. Without axial expansion joints, that thermal stress could buckle pipes, damage equipment, and rack up costly downtime. These joints absorb axial movement, relieving stress and maintaining integrity—no wonder they’re a staple for engineers working with thermal pipelines.

Top Applications of Axial Expansion Joints

Let’s break down where these marvels of mechanical flexibility show up most:

1. Power Generation Plants

In India’s thermal and nuclear power plants, axial expansion joints are crucial for high-pressure steam pipelines. They accommodate thermal expansion without putting strain on boilers or turbines. According to a report by the U.S. Department of Energy (Source), such joints can extend the life of steam systems by absorbing axial shifts of several millimeters to a few centimeters.

2. Oil & Gas Pipelines

Oil refineries and offshore rigs rely on robust piping networks that handle fluids at varying temperatures. Here, axial expansion joints minimize stress from sudden thermal shocks—especially during shutdowns or seasonal fluctuations. They help ensure pipelines remain leak-proof and stable.

3. Chemical & Petrochemical Facilities

Chemical processing plants handle corrosive fluids and fluctuating temperatures. Installing axial expansion joints prevents pipe deformation and joint fatigue, improving plant safety. A seasoned axial expansion bellows manufacturer often customizes these joints for chemical compatibility and higher performance.

Key Benefits That Make Them Indispensable

Besides thermal stress relief, there are more subtle but significant advantages that make these joints popular:

- Noise & Vibration Control: They dampen noise and vibration from pumps and compressors.

- Space Optimization: Their compact design reduces the need for large pipe bends.

- Lower Maintenance: Fewer pipe supports and anchors are needed, cutting installation costs.

Other Industries Embracing Axial Expansion Joints

Modern HVAC systems, water treatment plants, and even shipbuilding heavily depend on axial expansion joints. A large commercial building in Mumbai, for instance, might have hundreds of meters of HVAC ducting that expand with heat. The joints ensure these ducts stay sealed and aligned—small components, big impact.

Checklist: How to Pick the Right Axial Expansion Joint

Choosing the right joint isn’t a plug-and-play affair. Here’s a quick expert checklist:

- Temperature Range: Always match the joint to your system’s operating temperatures.

- Pressure Rating: Confirm the joint’s pressure capacity.

- Material Compatibility: Pick materials that resist corrosion and chemical reactions.

- Movement Capacity: Make sure it can handle the expected axial shifts.

FAQs About Axial Expansion Joints

1. What is an axial expansion joint used for?

It’s mainly used to absorb thermal expansion and contraction in pipelines, preventing stress and damage to the system.

2. Are axial expansion joints suitable for high-pressure systems?

Yes, when designed correctly by an expert manufacturer, they can handle high-pressure steam, oil, or gas lines with ease.

3. How often should axial expansion joints be inspected?

Regular inspection is advised every 6–12 months, depending on the operating conditions, to check for wear and ensure safe functioning.

4. Can axial expansion joints be customized?

Absolutely. A trusted axial expansion bellows manufacturer will tailor joints to specific size, material, and pressure requirements.

Final Thoughts

Whether it’s power, oil, or water, India’s vital infrastructure relies on smart, hidden heroes like axial expansion joints to keep things flowing smoothly. Next time you pass by an industrial plant, remember: it’s the small engineering details that make big operations possible.